Table of Contents

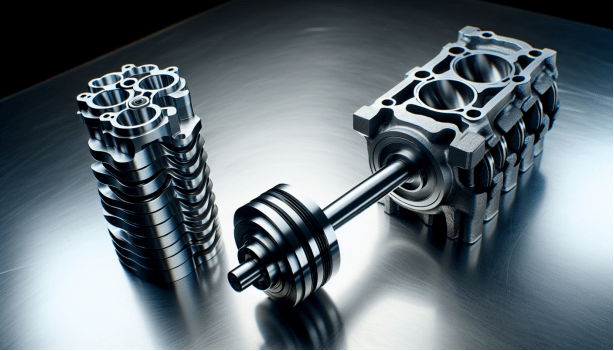

When building or maintaining an engine, checking crankshaft end play is an important step. Crankshaft end play refers to the movement of the crankshaft in the engine, and it plays a big role in the engine’s performance. If the crankshaft moves too much or too little, it can cause damage to the engine over time.

To start checking the crankshaft end play, you’ll need the right tools and a little patience. First, set the main caps on the engine and lightly tighten them to about 10 to 20 ft-lbs of torque. Next, tap the crankshaft with a soft mallet to make sure everything is aligned properly.

Step-by-Step Guide to Measuring Crankshaft End Play

Measuring crankshaft end play is a straightforward process but requires precision. Here’s how you can do it:

- Set the Crankshaft in Place

Begin by placing the crankshaft in the engine block. Set the main caps in position and lightly tighten the bolts to about 10 to 20 ft-lbs of torque. This will help keep the crankshaft in place while you measure the end play. - Use a Magnetic Base and Dial Indicator

Attach a magnetic base to the engine. Then, set the dial indicator on the crankshaft snout. This tool will help you measure the movement of the crankshaft. - Push the Crankshaft Forward

Gently push the crankshaft all the way forward, then zero the dial indicator. Now, push the crankshaft backward. The dial indicator will show how much the crank moves, which is the end play. - Measure the End Play

The end play should be within the recommended clearance for your engine type. If it’s not, adjustments will need to be made. For example, a small-block Chevy might need an end play between 0.003 and 0.011 inches.

By following these simple steps, you can measure the crankshaft end play accurately and ensure your engine’s health.

Common Mistakes to Avoid When Checking Crankshaft End Play

When checking crankshaft end play, there are a few common mistakes that can affect the accuracy of your measurements. Here’s a list of things to avoid:

- Not Using the Right Tools

It’s essential to use a dial indicator and magnetic base for accurate readings. Without the proper tools, your measurements may be off. - Improper Torque on Main Caps

If the main caps are not tightened properly, it can lead to inaccurate readings. Always follow the correct torque specifications to ensure the crank is securely in place. - Incorrect Alignment

Ensure the crankshaft is properly aligned before measuring the end play. Misalignment can lead to false readings and incorrect adjustments. - Skipping the Cleaning Process

After making adjustments to the thrust bearing or cleaning the crankshaft, make sure to thoroughly clean all components. Dirt or grit can affect the clearance and cause problems.

By avoiding these mistakes, you can ensure that your crankshaft end play measurements are correct and help prevent future engine issues.

How Crankshaft End Play Affects Engine Performance and Longevity

Crankshaft end play has a significant impact on how your engine performs and how long it lasts. If the clearance is too tight, the crankshaft may rub against the bearing surfaces, causing excessive friction. This friction can lead to overheating, premature wear, or even engine failure.

On the other hand, if the crankshaft end play is too loose, the crankshaft can move too freely, affecting the timing of the engine and causing instability. This can result in poor performance, reduced power, and increased wear on internal components.

How to Adjust Crankshaft End Play for Better Engine Efficiency

If you find that your crankshaft end play is outside the recommended range, adjustments can be made. Here’s a quick guide on how to do it:

- Clamp the Thrust Bearings Together

Use a hose clamp to hold the thrust bearings in place while making adjustments. Make sure both bearings are aligned properly. - Use Sandpaper for Fine Adjustments

For small adjustments, use fine-grit sandpaper (400 to 600 grit). Gently sand the bearing surfaces until you reach the desired clearance. - Measure the Clearance Frequently

As you make adjustments, measure the crankshaft end play frequently using the dial indicator to ensure you achieve the correct clearance. - Clean Thoroughly After Sanding

After making adjustments, clean the bearings and crankshaft thoroughly to remove any sanding residue. This will ensure there is no grit left that could damage the components.

By adjusting the crankshaft end play properly, you can improve the overall efficiency and performance of your engine

Conclusion

In conclusion, maintaining the correct crankshaft end play is essential for your engine to run smoothly and last longer. If the crankshaft moves too much or too little, it can cause damage and make the engine perform poorly.

Remember, measuring and adjusting crankshaft end play is a simple but crucial task when building or maintaining an engine. It ensures that the engine runs efficiently, with reduced wear and tear.

FAQs

Q: What is crankshaft end play?

A: Crankshaft end play is the small amount of movement allowed for the crankshaft inside the engine. It helps the engine run smoothly without parts rubbing or causing damage.

Q: Why is crankshaft end play important?

A: It ensures that the crankshaft can move slightly to handle pressure and forces, but not too much to cause damage to the engine parts.

Q: How do I measure crankshaft end play?

A: You can measure crankshaft end play using a dial indicator and a magnetic base, carefully pushing the crankshaft back and forth while taking the readings.

Q: How can I adj“How to Check Crankshaft End Play for a Long-Lasting Engine”ust crankshaft end play?

A: You can adjust it by carefully sanding the thrust bearing surfaces or using shims to achieve the correct clearance. Always measure frequently to avoid over-adjusting.

Q: What happens if crankshaft end play is wrong?

A: If the end play is too tight or too loose, it can lead to engine damage, poor performance, or even complete engine failure. Proper adjustment is crucial for a healthy engine.